Ballast Water Management: Focus Area for 2025 Port State Control Concentrated Inspection Campaign

Ballast Water Management: Focus Area for 2025 Port State Control Concentrated Inspection Campaign

- Understand How It Works

- Register to receive the Maritec-Naias PSC CIC Readiness Checklist

INTRODUCTION

The 2025 Port State Control Concentrated Inspection Campaign (PSC CIC) focuses on Ballast Water Management (BWM) from 1 September to 30 November 2025.

This initiative, led by the Paris and Tokyo MoUs, aims to ensure vessels comply with the IMO Ballast Water Management Convention, which helps prevent the spread of invasive aquatic species. It is expected that the majority of PSC MoUs will participate in this year’s CIC. Concentrated Inspection Campaigns focus on specific areas where a higher risk of non-compliance could exist. This could be evidenced by the number of deficiencies encountered, accidents or where new convention requirements have recently entered into force.

HOW DOES IT WORK?

Key Details:

- Timeframe: 1 September to 30 November 2025

- Scope: All ships subject to PSC in participating regions (Paris MoU, Tokyo MoU, and others)

- Focus: Operational and documentation compliance with BWM standards

- CIC Questionnaire:

- A standardized questionnaire will be used during inspections

- Click here to view a Sample Questionnaire seen on page 4 of the Tokyo MoU Press Release

- Helps ensure uniformity across PSC regimes

HOW CAN YOU PREPARE?

Click Here to Register for the Maritec-Naias PSC CIC Readiness Checklist*

- Share the Readiness Checklist with vessel crew to ensure crucial areas are compliant

- As longstanding experts in BWM Compliance Surveys & Reporting, Maritec-Naias can provide consultancy services to help ensure your vessels are CIC ready

*Upon receiving your registration our team will be intouch to assess your requirements & share the checklist

SINCE THE START OF THE PSC CIC, APPROXIMATEY 30 VESSELS ARE DETAINED DUE TO PSC INSPECTIONS WITH 12 VESSELS FOUND TO HAVE BALLAST WATER RELATED DEFICIENCIES*

Below please find a summary of key observations & findings from the list of detained vessels:

- A total of 22 ballast water management related deficiencies are recorded for the 12 detained vessels.

- Among the 12 vessels that were detained, 5 vessels have recorded ballast water detainable deficiencies.

- The 6 detainable deficiencies recorded for these 5 vessels include:

- 14811 – POLLUTION PREVENTION – BALLAST WATER – Ballast Water Management System

- 14813 – POLLUTION PREVENTION – BALLAST WATER – Ballast Water Management Plan – Implementation

- 14806 – POLLUTION PREVENTION – BALLAST WATER – Crew Training and Familiarization

- The other 7 vessels recorded 16 general ballast water deficiencies with the following as the most common:

- 14802 POLLUTION PREVENTION – BALLAST WATER (Ballast Water Record Book)

*Number of detained vessels are as per 09 September 2025 and subject to change as per ongoing updates on the Tokyo MoU website

A QUICK SUMMARY OF WHAT THE MARITEC NAIAS CHECKLIST PLACES THOROUGH EMPHASIS ON (CLOSELY BASED ON WHAT IS EXPECTED FOR INSPECTORS TO CHECK FOR)

- Ballast Water Record Book (BWRB)

- Accurate and complete entries for all ballast operations (intake, transfer, discharge) with date, time, location, and volume

- Use of electronic BWRBs must be backed by flag state approval letters kept onboard

- Consistency between BWRB, BWMS logs, and actual operations

- Ballast Water Management System (BWMS)

- Functionality and maintenance records

- Reporting of malfunctions and use of contingency measures

- Crew familiarity with system operation

- Ballast Water Management Plan (BWMP)

- Up-to-date and integrated into the Safety Management System

- Clear procedures for normal and emergency operations

- Designated responsible personnel and port-specific details

- Crew Familiarization

- Inspectors will assess whether crew members understand:

- How to operate the BWMS

- What to do in case of system failure

- How to properly record ballast operations

Note: As always, the CIC is part of regular PSC inspections. Inspections are therefore not limited to BWM; however, during the first PSC inspection in a participating MoU, the CIC topic will be addressed.

For more information on Maritec Naias Ballast Water Testing services and other Discharge Water Compliance services please visit Maritec Services and Naias Services .

Sources:

- PSC CIC 2025 on ballast water management and DNV’s PSC Top 18

- Paris MoU 58th Committee meets in Malmö, Sweden | Paris MoU

- Press release

- Press-release-on-2025-CIC-BWM-final.pdf

- https://apcis.tmou.org/isss/public_apcis.php?Mode=DetList

Newsletter & Whitepapers

High Catalyst Fines (Catfines) found at Singapore Ports

High Catalyst Fines (Catfines) found at Singapore Ports

FINDINGS & INSIGHTS

During the period of 25 July 2025 to 02 August 2025, Maritec Pte Ltd (hereafter referred to as Maritec-Naias) tested forty samples representing VLSFO deliveries from various suppliers at Singapore ports, which indicated Aluminium and Silicon (Al+Si) concentrations ranging from 51 mg/Kg up to 120 mg/kg.

Maritec-Naias findings of Al+Si concentrations in the forty samples tested were as follows:

- Two samples indicated Al+Si concentrations above 100 mg/Kg levels

- Eleven samples indicated Al+Si concentrations above 60 mg/Kg levels

- Twenty-nine samples indicated Al+Si concentrations between 51 to 60 mg/Kg levels

While thirty eight out of forty samples fell within the specifications of ISO8217:2005 (80 ppm) and even within the ISO8217:2010/2017 specifications (including permitted limits of 72 PPM as per ISO4259 for a single test result), the Catfines content can still be considered at high levels.

Aluminium and Silicon are main classes of abrasive solids found in fuels. High levels of abrasive particles at the engine inlet may lead to abnormal wear and tear of the fuel system components, piston rings and cylinder liners. In fact, to control the amount of catalyst fines delivered to the engine, many engine builders specify a maximum limit of 15 mg/kg of Aluminium plus Silicon at the engine inlet.

An efficiently operating fuel purification system is the preliminary method of removing these particles. Measuring the fuel’s Aluminium and Silicon concentrations before and after the system’s centrifuge provides an indication of the efficiency of the purification system in removing catalyst fines.

OUR RECOMMENDATIONS

Maritec-Naias recommends collecting samples from within the fuel system at points such as the fuel oil tank transfer pump, before and after centrifuge, service tank and after filter samples to check the fuel cleaning efficiency.

Maritec-Naias states, while all presented findings are true, this document, does not reflect on the overall quality of fuel being supplied in the Singapore region. If you intend to bunker at this region please request a Certificate of Quality prior to loading.

Maritec-Naias can assist you with further information on quality of bunkers tested in different regions. If you require any other information or assistance do not hesitate to Contact us.

DOWNLOAD BUNKER_FLASH_BF202508-07

Bunker Flash

BioFuel Testing

Future forward testing as per ISO 8217 requirements and enhanced testing solutions for pre-emptive risk management

Global shipping accounts for 2–3% of worldwide emissions and the Maritime industry is working towards net zero emissions by 2050. As temporary measures, the IMO has established targets to achieve: a 30% reduction in emissions by 2030 (compared to 2008), and a 70–80% reduction by 2040. BioFuel, serving as a ‘drop-in’ fuel alternative that necessitates minimal changes to existing machinery, offers the Maritime industry a viable decarbonisation solution during these interim periods.

Maritec-Naias supports this transition by offering comprehensive testing solutions for BioFuels and Bio-alternatives, such as HVO and CNSL, through our Marine Fuel Testing Programme (MFTP) as well as tailored enhanced testing solutions.

Our services & solutions include:

- ISO8217 Routine Analysis (MFTP)

- FAME Content Determination (Quantitative)

- Net Calorific Value Measurement

- Cold Flow Properties (Cloud Point/CFPP for Bio-Distillate)

- Cold Flow Properties (WAT/WDT for Bio-Residual)

- Microbial Detection

- Chemical Contamination Screening Analysis (Qualitative)

- Unsaturated Fatty Acid Determination (Chemical Contamination Screening Plus)

- BioFuel Fuel Quality Assessment

- Shelf-life Assessment of BioFuel

Why choose Maritec-Naias?

- Bespoke Biofuel Testing programme to support trouble free usage of BioFuels in fuel systems

- Expertly designed programme addresses quality issues arising from various types of Bio-blends – created by blending 100% Bio-diesel (often referred to as FAME) with traditional marine fuels

- Customisable testing options available to monitor BioFuel degradation issues on compatibility, stability and acidity during storage onboard

- Comprehensive R&D work conducted on FAME feedstocks and blending variations for optimal monitoring of BioFuel’s unique behavioural characteristics

- Deep technical know-how from shipboard experiences and accumulative analytical data on BioFuel samples obtained from key bunkering ports for accurate risk mitigation during switchover to Biofuel

- Global laboratory coverage: China, Greece and Singapore

- Fast turnaround time on lab testing & reporting with 24/7 technical support

- Training and consultancy on fuel transition and emissions compliance mechanisms

Would you like to learn more about out services? Get in contact

Other services and

solutions for a greener

Maritime Future

Nothing found.

Nothing found.

Nothing found.

NDT & UTM Services

Third party and independent Non-Destructive Testing (NDT) & Ultrasonic Thickness Measurement (UTM) services available in Singapore

Through our business arm of Poly NDT Pte Ltd, established in 1975, we specialise in delivering highly reputable, accredited and professional Non-Destructive Testing (NDT) and Ultrasonic Thickness Measurement (UTM) services in Singapore to ensure the integrity, safety, and compliance of our clients assets — without causing damage or downtime.

With decades of honed experience, our team possesses the know-how and unique capabilities to tailor services as per our client’s requirements, while ensuring a stringent Code of Practice.

Our key services & solutions include:

- Ultrasonic Testing (UT) – a family of NDT techniques based on the propagation of ultrasonic waves in the object or material tested to detect flaws in materials & welds.

- Magnetic Particle Inspections (MPI) – an NDT method where a magnetic field detects surface, shallow sub-surfaces & discontinuities in ferromagnetic materials & welds.

- Radiography Testing (RT) – an NDT or Examination method for examining the internal structure of any component & welds to determine its integrity.

- Dye Penetrant Inspections (DP) / Liquid Penetrate Inspection (LPI) / Penetrant Testing (PT) – a widely applied low-cost method used to check surface breaking defects in all non-porous materials (metals, plastics, or ceramics) & welds.

- Eddy-current Testing (ET / ECT) – one of many electromagnetic testing methods used in NDT, which uses electromagnetic induction to detect and characterise surface and sub-surface flaws in conductive materials & welds.

- Hardness Testing (HT) – a method used to measure a material’s resistance to permanent deformation at its surface, by pressing a harder material into it.

- Ultrasonic Thickness Measurement (UTM) – using high-frequency sound waves to penetrate material. When the waves encounter an interface (such as back wall or corrosion), they reflect back. The time taken for the waves to travel through the material and return is measured to calculate the thickness.

Why choose Maritec-Naias?

- Decades of trusted experience, backed by professionalism and an impeccable reputation

- One of the select few companies in Singapore to be approved to conduct work for the Singapore Navy & US Navy

- Technicians trained at accredited institutes in Singapore and CSWIP (UK)

- SAC SINGLAS & an ISO 9001 certified company

- Teams consist of ASNT level III engineers authorised to train and qualify NDT technicians

- Approved to carry out ultrasonic ship hull inspections and other NDT by 11 major Classification Societies, namely, LR, ABS, NK, BV, DNV, RINA, CR, CCS, SCM, IRS & KR

- Consultancy & advisory services aimed at providing best-fit solutions

Would you like to learn more about out services? Get in contact

Other services and

solutions for a greener

Maritime Future

Nothing found.

Nothing found.

Nothing found.

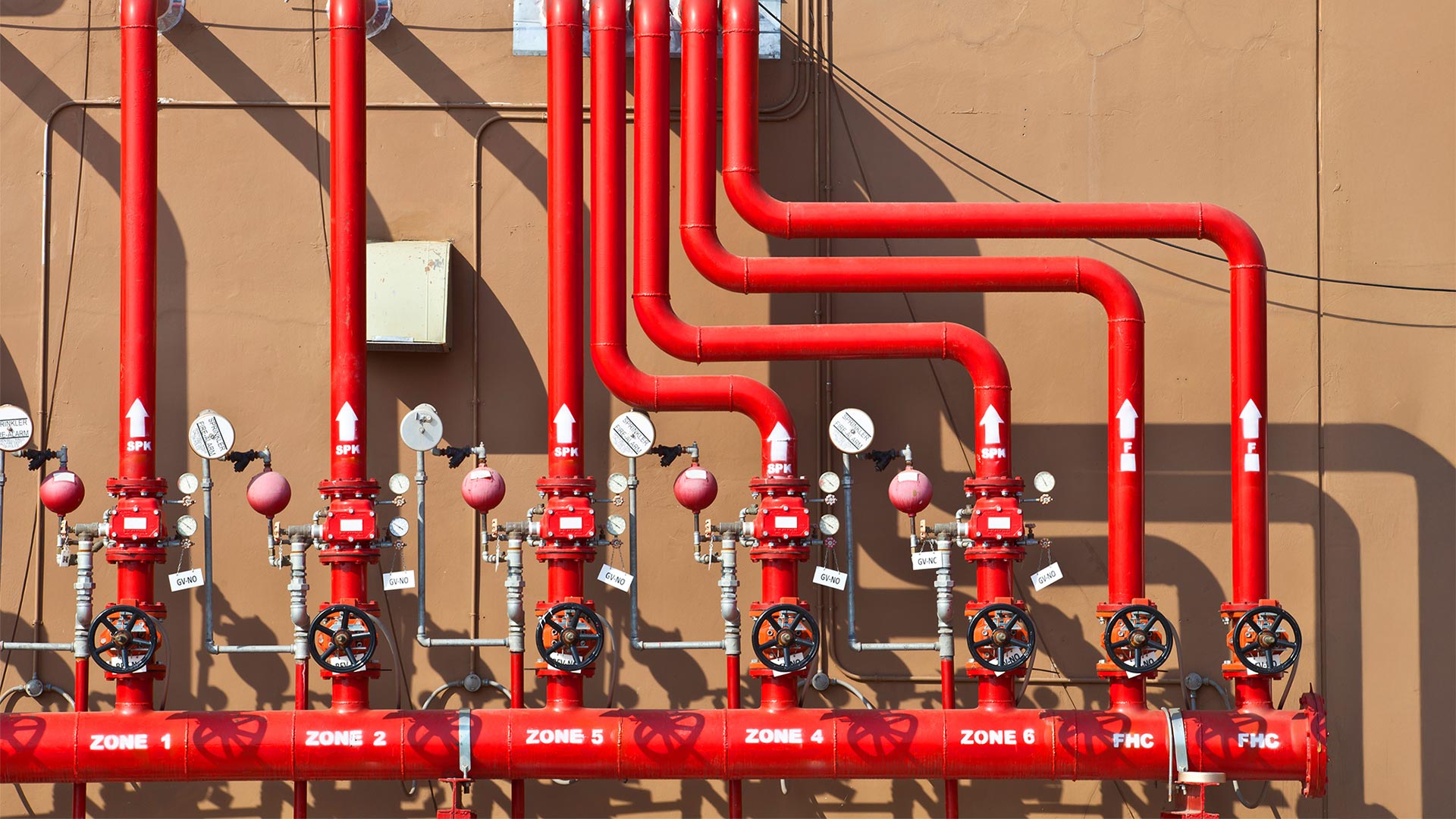

Fire Fighting Foam Analysis

Expert analysis in adherence with IMO regulations to protect crew safety & minimise environmental impact

The International Maritime Organisation (IMO) has amended the SOLAS Convention and High-Speed Craft (HSC) Codes to ban the use and carriage of firefighting foams containing perfluorooctane sulfonic acid (PFOS) above 10 mg/kg, starting 01 January 2026. This requirement applies to both new and existing ships and crafts.

New ship requirements:

- Ships and crafts constructed on or after 01 January 2026 are to comply with the new requirements at the time of delivery.

Existing ship requirements:

- Existing ships and crafts are to comply with the new requirements no later than the date of the ‘first survey’ on or after 01 January 2026. The term ‘first survey’ means the first annual survey, the first periodical survey, or the first renewal survey, whichever is due first after 01 January 2026.

The core reason behind the prohibition is that PFOS belongs to the larger family of PFAS (Per- and polyfluoroalkyl substances), commonly referred to as “forever chemicals”. It is persistent, bioaccumulative, and toxic, with significant environmental and health risks. Additionally, PFOS has been identified for a worldwide phase-out in accordance with the Stockholm Convention on Persistent Organic Pollutants.

Shipowners, Operators, and Masters must be actively vigilant in adhering to the prohibition by securing a manufacturer’s declaration or laboratory test report promptly to verify the concentrate of any existing foam onboard, and thereafter, complies with the new requirements. If any fire-fighting media containing PFOS is detected onboard, prompt action is required to remove or replace the material by the deadline or before the date of the ‘first survey’ after 01 January 2026.

For customers unable to obtain a declaration from the manufacturer of existing foam onboard, Maritec-Naias’s analyse for PFOS can be conducted alongside routine analysis for other parameters.

Testing Frequency & Parameters as per IMO guidelines:

To ensure foam concentrate remains effective and has not degraded due to age, contamination, or environmental exposure, it must be periodically tested according to IMO guidelines (MSC/Circ.670 for High-Expansion foam concentrate and MSC.1/Circ.1312 for Low-Expansion foam concentrate). The first periodic test must be performed not more than 3 years after the foam concentrate has been supplied to the ship, and after that, every year. Parameters for testing include expansion ratio, drainage time, pH, density, and fire performance criteria. Chemical stability test for protein-based alcohol-resistant foam concentrates, shall be performed prior to the delivery of the ship and annually thereafter.

The fire protection system shall be maintained and inspected regularly as per MSC.1/Circ.1432. For the five-year service, Maritec-Naias performs testing of the foam solution to confirm that the mixing ration tolerance is within the applicable limits

To support our customer’s in adherence with latest IMO regulatory requirements, Maritec-Naias offers Fire Fighting Foam Analysis services, which include:

- PFOS Concentrate Analysis for existing foam onboard (incase stakeholders are unable to obtain manufacturer’s declaration)

- Annual/Periodical Analysis (Foam Concentrate)

- Annual/Periodical Analysis (Alcohol-Resistant Foam Concentrate)

- Mixed Produced Foam Analysis (5 yearly)

- PFAS (20 analyte) Analysis includes PFOS, PFOA & PHFxS

Why choose Maritec-Naias?

- Rapid TAT for analysis and report delivery

- ISO 17025 Accredited Testing

- Tailored testing service packages to suit customers varied needs and budgets

- Longstanding experience in testing for adherence to maritime regulatory requirements

Would you like to learn more about out services? Get in contact

Other services and

solutions for a greener

Maritime Future

Nothing found.

Nothing found.

Nothing found.

Maritec Naias Conducts Seminar & Attends Indonesia Maritime Week 2025

Maritec Naias attends responsible ship recycling (RSR) forum 2025 in London

Attending and presenting at the Indonesia Maritime Week 2025 in Jakarta was a rewarding experience!

We had an impressive turnout for our Seminar on ‘Inventory of Hazardous Material (IHM): Lifecycle Management of Ships’ & ‘IHM Certification’, which was organized in collaboration with the China Classification Society (CCS).

Our expert-led Seminar was astutely developed to convey vital insights regarding the key IHM regulatory requirements of the ratified Hong Kong Convention (HKC), which is set to come into effect in June 2025. As the Maritime industry increasingly prioritizes sustainable practices and regulatory compliance, comprehending the complexities of the IHM requirements remain essential.

During one day of the Maritime week, we also participated in the insightful Ship Recycling Committee meeting, which proved to be a highly effective forum for exchange of ideas and industry knowledge on the critical role of IHM compliance in meeting Responsible Ship Recycling (RSR) targets.

MARITEC-NAIAS provides leading HKC Compliance Services (IHM Prep & IHM Maintenance), Asbestos Surveys, Management, Certification & Removal services, and RSR Supervision services & solutions.

News

Maritec Naias at BARI SHIP 2025 Expo

Maritec Naias at BARI SHIP 2025 Expo

Participating in BARI SHIP 2025 at Imbari, Japan, was a refreshing experience!

Engaging in fruitful discussions with both existing clients and other industry players alike, was the highlight of the event. It provided us with the chance to thoroughly explore how our comprehensive solutions can meet their requirements.

Additionally, it enabled us to assess the areas where market shortcomings or challenges are present – largely contributing to the sparks of innovation, which fuel the development of our new and enhanced solutions.

Our two seminars – ‘FuelEU Maritime Regulation: Financial Modelling for Cost Optimisation’ and ‘Best Practices in BioFuel Usage’ – were particularly well-received.

The first seminar focused on the Fuel EU Maritime Regulation (effective from 01 January 2025) highlighted the advantages of reduced operating costs achieved through compliance with reduction targets. A demonstration to apply to the regulation’s operational mechanism allowed attendees to witness the effects of adopting about 12% of B24 in lowering overall expenses including EU ETS allowances despite having a cost premium for conventional fuel.

The second seminar focused on the use of biofuels discussed key issues related to the management and risks of biofuels in the shipping sector. To understand the unique risks linked to biofuels, we provided an in-depth explanation of their specific “FAME” behaviours and characteristics such as possible degradation of Oxidation Stability and possible increase in Fatty Acids over time.

On the last day of the Expo, children of all ages visited our booths, instantly injecting extra joy and laughter into the atmosphere! We were thrilled to meet the young innovators of the future, and it was our pleasure to share a few treats and gifts with them.

MARITEC-NAIAS has the unique capabilities to fulfil customers’ Marine Energy testing requirements (for conventional fuels, BioFuels and Methanol) and Environmental Compliance Testing needs. For further information on how we can assist you, please contact us via email at admin@maritec.com.sg

News

Maritec-Naias Attends Responsible Ship Recycling (RSR) Forum 2025 in London

Maritec-Naias attends responsible ship recycling (RSR) forum 2025 in London

On 14 May 2025, the Responsible Ship Recycling (RSR) Forum was held in London and attended by our Global Sales Director Toby Brooks and West Europe Sales Manager Konstantina Aravantinou.

The forum focused on navigating evolving regulations and expanding ship recycling options, influencing core service offerings of MARITEC-NAIAS in Marine Environmental Compliance.

Toby expressed, it was a productive day, where decision makers and industry stakeholders convened to address RSR needs, including the impact of forthcoming regulations. Most notably the ongoing debates on ships recycling over Hong Kong and Basel Convention, debating potential overlaps and even conflicts between the two conventions. The forum also delved into topics like ESG reporting, finance institution’s roles in sustainability, circular economies and industry stakeholders’ responsibilities in steel recycling.

The day’s success was fundamentally a collective effort to review industry progress and the important milestones ahead in responsible recycling and decarbonization objectives.

We thank Norton Rose Fulbright law firm for a fantastic venue and the forum organizer’s, Riviera, for an inspiring forum!

News

One-stop CTI Shanghai LAB now renamed & offering Enhanced Fuel Oil Testing

One-stop CTI Shanghai LAB now renamed & offering Enhanced Fuel Oil Testing

Looking to the future, CTI-MARITEC’s one-stop laboratory in Shanghai is revamped and renamed to offer enhanced Fuel Oil Testing including Methanol Biofuel Testing.

CTI-MARITEC is widely known for its technology-forward approach, professionalism and uncompromised precision in the field of fuel oil testing. The laboratory previously known as ‘CTI-MARITEC Maritime Services China Fuel Oil Laboratory’ has been now officially renamed as ‘CTI-Shanghai Center Fuel Oil Laboratory’ and further equipped to provide customers with a broader range of testing services, including marine Methanol Biofuel testing.

New Name, New Beginnings

In light of ongoing market expansion and the evolving demands of our clients, the decision to rename our laboratory represents a strategic initiative aimed at remaining at the forefront of fuel oil testing services. The new name embodies a fresh start and reflects our commitment to enhancing our service offerings through the implementation of industry-leading practices and advanced technology.

What’s New?

Deepening of Marine Fuel Oil Testing: Building upon our established marine fuel oil testing protocols, the integration of advanced equipment and enhanced testing methodologies results in improved efficiency and precision, facilitating more effective oversight of the quality of vessel fuel oil.

Marine Methanol Biofuel Testing: In light of the increasingly rigorous global standards for decarbonization and the reduction of Greenhouse Gas (GHG) emissions within the shipping sector, marine Methanol is garnering heightened interest as a clean alternative bio-fuel. The CTI-Shanghai Center Fuel Oil Laboratory has taken proactive measures by providing testing services for marine Methanol. In accordance with ISO 6583 and GB/T42416 Methanol standards, our laboratory conducts precise assessments of purity, moisture content, impurities, and other critical parameters of marine Methanol. Our comprehensive and dependable testing services assist the maritime industry in making consistent progress towards decarbonization.

Expansion of Automotive Urea Testing Capabilities: Several new parameters for testing automotive urea have been introduced, encompassing full capacity assessments in accordance with GB 29518-2013 and ISO 22241-1 standards, as well as full capacity evaluations based on ISO 18611-1. These parameters thoroughly address the quality metrics for both automotive urea and marine urea aqueous solutions, facilitating robust and efficient management of exhaust treatment systems in automotive and marine applications.

Extensive Gasoline and Diesel Testing Parameters: A comprehensive array of tests is available for gasoline, including key metrics such as Motor Octane Number, Research Octane Number, anti-detonation index, distillation range, vapor pressure, and gel content. For diesel, testing services encompass density, cetane number, cetane index, distillation range, and oxidative stability, among others. Together, these extensive testing capabilities comply with the rigorous standards for gasoline and diesel fuel quality across various regions, ensuring the necessary safeguards to mitigate air pollution.

Best in Class Accreditation to ensure utmost reliability

The laboratory is equipped with state-of-the-art testing apparatus and is supported by a highly skilled technical team that adheres rigorously to international testing standards and protocols. The accreditations from CMA (China Metrology Accreditation) and CNAS (China National Accreditation Service for Conformity Assessment), recognized as the most reputable in the industry, guarantee that the test reports produced are scientific, precise, and trustworthy, thereby offering clients the highest level of confidence in quality standards.

Leveraging the name change as a strategic opportunity and bolstered by enhanced testing capabilities, the CTI-Shanghai Center Fuel Oil Laboratory will persist in its commitment to professionalism, efficiency, and fairness. It aims to deliver comprehensive and integrated testing solutions for the fuel oil sector, collaborate with clients to foster a prosperous future, and advance the high-quality development of the fuel oil and associated industries.

News

CNSL BioFuel Blended in Marine Fuel

CNSL BioFuel Blended in Marine Fuel

Findings & Insights:

In the recent-past few months several ships in the Singapore and Rotterdam area reported operational problems including fuel sludging, injector failure, filter clogging, system deposits and corrosion of turbocharger nozzle rings.

In light of the reported problems, CTI-Maritec swiftly carried out extended Gas Chromatography Mass Spectrometry (GC-MS) testing for Very Low Sulphur Fuel Oil (VLSFO) samples from these said vessels.

GC-MS testing by Solid Phase Extraction (SPE) method showed the presence of high concentrations (>10000 PPM) of cardol, cardanol, anacardic acid and other alkyl resorcinols. All mentioned compounds, which are substituted long chain phenols, indicated the fuel was blended with Cashew Nutshell Liquid (CNSL) from undeclared source materials or production processes.

CNSL is a non-FAME BioFuel, which is a naturally occurring byproduct of the cashew nut industry and acts as a low-cost alternative renewable fuel. It’s a substituted phenol, which is highly reactive and less stable owing to its high iodine value. The application of CNSL is known in the production of plastic, resin, adhesives, laminates, and surface coatings. CNSL has high acid values and is therefore highly corrosive as well. High Potassium found in CNSL blend fuels cause serious post-combustion deposits and corrosion of turbocharger nozzle rings.

The latest version of ISO:8217 specifies the accepted BioFuels such as FAME based biofuels, Hydrotreated Vegetable Oil (HVO), defined by the specifications of EN 14214, ASTM D6751 and EN 15940 respectively. These fuels are now established and acknowledged by equipment manufacturers (OEM), Classification Societies (Class) and flag Administrations as ‘drop-in’ fuels. There is no specification available for CNSL from any authorised body like above.

CTI-Maritec Recommendations:

CTI-Maritec recommends that shipowners should not use 100% CNSL as a marine fuel or use CNSL as a blending component in marine fuel, which is contrary to the guidance by IMO on best practices for suppliers on the quality of fuel oil delivered to ships.

MEPC.1 /Circ. 875/Add.1 section ‘5’ – where it states that:

5.3 Blend components should be tried and tested so that their typical properties and suitability for bunker production and how they combine with other components is well understood…… and

5.4 Where there are any uncertainties as to the nature and quality of blend component, any issue should be identified and resolved before its use in the production of bunkers.

Furthermore, CTI-Maritec recommends not using unestablished bioproducts in marine diesel engines. Blending these substances in a marine fuel might meet specifications as per ISO:8217 tables 1 and 2 parameter limits but may not fulfil general requirements of compliance as per Clause 5 of ISO:8217.

CTI-Maritec can assist you with further information on the quality of bunkers tested in different regions. For further information or assistance please do not hesitate to Contact us.