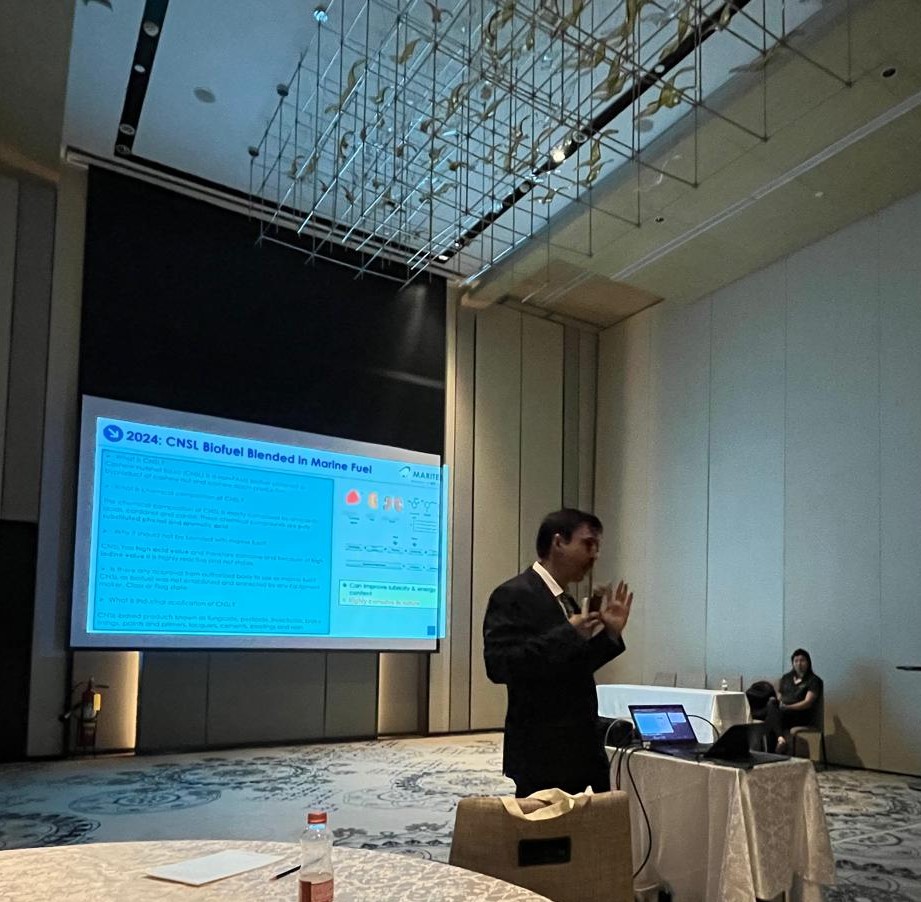

Maritec-NAIAS Presents Technical Seminar to ClassNK Kobe Office on Best Practices of BioFuel Usage

Maritec-Naias Presents Technical Seminar to ClassNK Kobe Office on Best Practices of BioFuel Usage

It was our pleasure to present to the maritime classification society experts at the ClassNK Kobe Office in Japan.

Our senior technical specialist in Fuel Quality Testing & Management led the session, deep diving into key insights on the topic of ‘Best Practices of BioFuel Usage’.

Setting the narrative, focus was initially placed on understanding the current landscape of BioFuel usage, the main regulatory drivers and commercial considerations. Understanding these foundational aspects is key in understanding the current realities faced in the market.

Building upon this, our specialist moved onto discussing the behavioral characteristics and testing requirements unique to BioFuels – all directly related to important monitoring needs for the optimal usage and management of BioFuels. Essential technical requirements related to BioFuel Bunkering were also covered indepth to further highlight the specific bunkering needs of Biofuels as compared to conventional fuels.

The keen interest shown by ClassNK in this space is reflective of the growing emphasis on achieving sustainability and decarbonization goals in the shipping industry. In this crucial undertaking, adopting reliable and professionally vetted processes will be central in its success.

We thank ClassNK Kobe Office for the privilege of sharing our expertise.

News

Maritec-NAIAS Sponsors & Attends 2025 Annual IBIA Gala Dinner

Maritec-Naias Sponsors & Attends 2025 Annual IBIA Gala Dinner

The annual IBIA Gala Dinner on Monday, February 24, at the Grosvenor House Hotel, London, was a house-full event, bringing together 1,200 industry professionals.

As one of the evening’s sponsors, Maritec-NAIAS, was pleased to witness the strong turnout, reflecting IBIA’s growing contribution towards the future of sustainable shipping and decarbonization.

Representing Maritec-NAIAS, our team members attended the dinner, actively engaging with industry leaders and supporting both, long standing and new clients alike, from the international bunker sector.

We thank IBIA for organising an interactive evening.

News

Maritec Attends 2025 CTI Annual Conference

Maritec Attends 2025 CTI Annual Conference

Thank you, Centre Testing International Group Co., Ltd. (CTI), for an invigorating 2025 CTI Annual Conference.

Maritec, as a member of the CTI group, was able to participate in this year’s recent Annual Conference held close to Shenzhen where CTI is headquartered. The Annual, like the years before, served for renewed alignment for time-tested strategies, introduction of new goals and visions, and finally, acknowledgment of the outstanding contributions of individuals in 2024.

AI and Technology became additional focal points this year to support CTI’s Testing, Inspection & Certification (TIC) efforts for continued quality assurance while remaining competitive for the market. Previous focus on global expansion also remained a central topic to increase presence and be within short reach of our clients. It was re-emphasized by top leadership that we shall always remain obsessed with our customer’s needs thereby aiming to fulfill those needs accompanied with the best possible customer experience.

The CTI Group, established in 2003, is a member of the TIC Council and operates with more than 13,000 employees working from a network of over 150 laboratories and more than 260 offices in over 90 cities around the world. Diversified accross 18 industries globally, the group is committed to supporting clients as a one-stop solution provider for Testing, Inspection, Certification, Calibration, Audit, Training & Technical services. In staying true to its mission of “Building Trust for a Better Life”, the CTI Group unwaveringly adheres to its core values of “Integrity, Collaboration & Team Advancement, LEAN, Innovation, and Client Centricity”, with Sustainability as the cornerstone of its belief system.

As CTI continues to expand its business to bring greater value to customers, the acquisition of Maritec & NAIAS Labs, in 2020 and 2024 respectively, worked to consolidate and strengthen all CTI’s Marine & Marine Fuel testing and inspections services. We can expect the future to hold more integrations in the commitment towards building stronger, smarter, and faster solutions for customers. Today, leveraging on the CTI Group’s resources and wide expertise, Maritec-NAIAS delivers leading services & solutions to 1650+ customers worldwide from a network of 15 offices based globally and 3 strategically located laboratories, operating 24×7, in Singapore, China & Greece.

News

Maritec-NAIAS presents Technical Seminar on Chemical Contamination Issues in Marine Fuels

Maritec-Naias presents Technical Seminar on Chemical Contamination Issues in Marine Fuels

It was our pleasure to partner with Aderco to conduct a technical seminar on ‘Chemical Contamination Issues in Marine Fuels’ for the team in Chennai, India on 14th February 2025.

Our Maritec-NAIAS expert set the stage by commencing with a look back at the history of key incidents of chemical waste contamination in the bunkering industry from the past ten years. Alongside this, vital insights on the main reasons behind the issues faced and the inevitable risks involved were dwelled into.

Moving to present day scenarios, as we observe the growing adoption of Biofuels (in efforts to meet the IMO strategy towards greater sustainability), our experts addressed the critical questions of contamination risks involved in the use of Biofuel (both FAME based, and non-FAME based) in the shipping industry. To understand the unique risks associated with Biofuels, detailed explanations were presented on their specific chemical behaviours and characteristics, namely ‘Stability’, which are directly linked to their composition.

Our team went on to share expert guidance on the optimal pre-emptive testing needed to mitigate the prevalent risks associated with bunker contamination from conventional fuel and Biofuels. Furthermore, direction was provided on bunker negotiations and claim processes, all in aid of stronger and smarter marine fuel management.

We thank Aderco for this knowledge sharing opportunity – one of immense importance in ensuring optimal marine fuel management for today and the future.

News

ISCC EU & ISCC Plus Certification for Sustainable Marine Fuel Management

ISCC EU & ISCC Plus Certification for Sustainable Marine Fuel Management

What is ISCC Certification?

International Sustainability and Carbon Certification (ISCC) is a globally applicable sustainability certification system, which covers all sustainable feedstocks, including agricultural and forestry biomass, bio-based and circular materials and renewables.

Certification under the ISCC standard assures a fully transparent and deforestation-free supply chain, protection of land with high biodiversity value and high carbon stock. The ISCC standard complies with human, labor and land rights, as well as good management practices.i

iSCC offers several sustainability schemes for energy, such as ISCC EU and ISCC Plus. ISCC EU is recognized by the EU Commission to validate sustainability criteria in fuel. The scheme’s extensive measures will check-off the end-to-end needs in maintaining credible sustainability practices along its supply chain. With the ISCC EU recognized under the EU’s revised Renewable Energy Directive (“RED II”) as well as other major energy markets, ISCC EU certification is set to play a major role under the upcoming FuelEU Maritime regulation, among others, and beyond.

Why choose ISCC Certification to help achieve Maritime sustainability goals?

The approach of ISCC schemes encapsulates critical aspects, which work in tandem with the EU and IMO regulatory stipulations and associated documentary requirements such as:

- Lifecycle Assessment: Examines emissions at production, use, and end.

- Proof of Sustainability (PoS) Documents: Provides supporting documentation to validate that Biofuels batches are traceable to their sustainable feedstocks.

- Annual Audits: Includes annual audits to ensure compliance with sustainability standards.

Keep in Mind!

The FuelEU Maritime Regulation, effective 01 January 2025, for all ships trading within the EU or European Economic Area (EEA), will have to employ sustainable fuel to avoid penalty.

Sustainable fuel used by vessels must be sourced and procured from an entirely certified supply chain.

Sustainable Marine Fuels with ISCC covered under the ISCC EU and ISCC EU PLUS Schemes

Sustainable marine fuels covered under ISCC EU & ISCC PLUS Certification include:

- Biofuels (such as FAME, bio-methanol and other liquid fuels for the transport sector produced from bio-based feedstocks)

- Renewable Fuels of Non-Biological Origin (RFNBO)

- Recycled Carbon Fuels (RCF)

Keep in Mind!

The 2023 IMO GHG Strategy envisages a reduction in carbon intensity of international shipping (to reduce CO2 emissions per transport work), as an average across international shipping, by at least 40% by 2030. The 2023 IMO GHG Strategy also includes a new level of ambition related to the uptake of zero or near-zero GHG emission technologies, fuels and/or energy sources which are to represent at least 5%, striving for 10% of the energy used by international shipping by 2030.

Sustainable fuel with lower emissions in favour of Carbon Intensity Indicator (CII) measures also requires similar sustainability certification, and ISCC EU PoS is a recognized document.

Newsletter Source: https://www.iscc-system.org/

Maritec-NAIAS offers holistic training & consultancy services to Energy Traders supplying sustainable marine fuel. We train and enable them to achieve ISCC EU certification necessary for them to supply sustainable fuel recognized by Fuel EU Maritime (and RED II) to reduce penalty and required EU Allowances on vessel owners.

Click Here to read about the successful completion of ISCC certification and audit services for our customers.

For more information on Training, Consultancy/Advisory, Auditing and ISCC Certification services write to us at admin@maritec.com.sg.

Click Here to Download the PDF copy of the Newsletter

Newsletter & Whitepapers

Congratulations to Global VE Trading Pte Ltd!

Congratulations to Global VE Trading Pte Ltd!

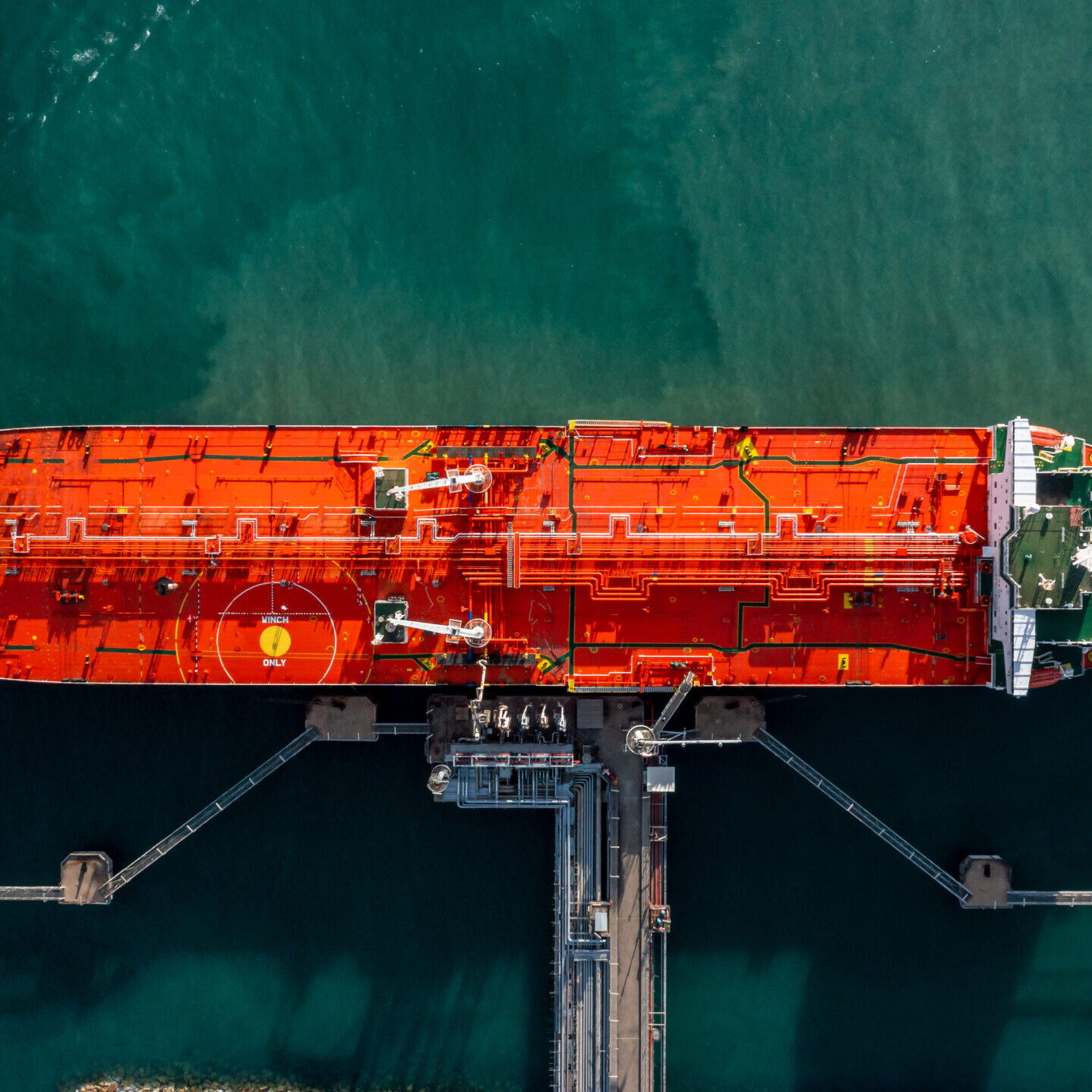

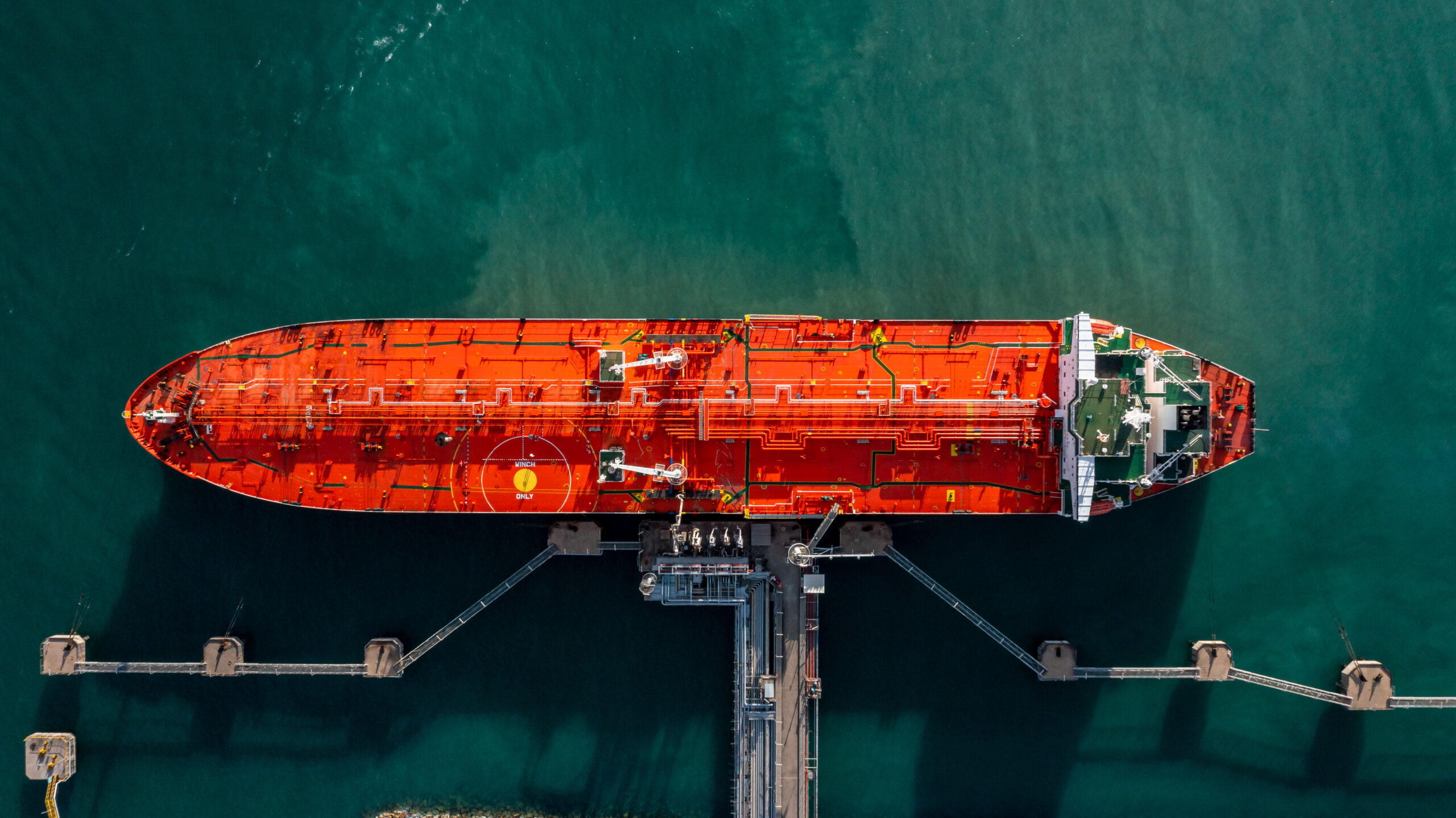

Maritec-NAIAS would like to congratulate Global VE Trading Pte Ltd for their addition of another VLCC, SOUTHERN EMPEROR, to their fleet of floating storage units as an ISCC Certified Logistic Centre.

This milestone reflects the dedication to sustainability and decarbonization efforts within the maritime industry.

Maritec-NAIAS wishes Global VE Trading Pte Ltd continued success as they journey towards a more sustainable future.

Click Here to read another update on the successful completion of ISCC certification and audit services for our customers.

For more information on Training, Consultancy/Advisory, Auditing and ISCC Certification services write to us at admin@maritec.com.sg.

News

Why accurate testing of Energy Content (Net Heat of Combustion) is essential for Bio-Marine Fuels

Why accurate testing of Energy Content (Net Heat of Combustion) is essential for Bio-Marine Fuels

Introduction

Bio-marine fuel is widely adopted as a drop-in fuel to achieve the current emission requirements in the shipping industry. ISO 8217:2024 specification allows bio-marine fuels to contain up to 100% fatty acid methyl ester (FAME). The major production route of FAME is transesterification of vegetable oils, animal fats or used cooking oils with methanol using alkaline catalysts. The ISO 8217:2024 version has included additional test parameters to measure FAME content, energy content and oxidation stability for bio-marine fuels.

Accurate Net Specific Energy (NSE) assists with efficient fuel consumption management

In this newsletter article, we review why one of the most important testing parameter or property of bio-marine fuel is Energy Content. Accurate measurement of NSE for energy content of bio-marine fuels is essential for efficient fuel management onboard ships with respect to:

- Fuel consumption

- Voyage planning

- Operating cost

- Machineries or equipment performance

- Emission & environmental implications

Why accurate testing of Energy Content is an essential test parameter for Bio-marine fuel

Marine fuel containing FAME typically has lower energy content compared to conventional marine fuels.

The heating value of a fuel is the total energy released as heat when a fuel undergoes complete combustion with oxygen under standard conditions. The chemical reaction is typically a hydrocarbon reacting with oxygen to form carbon dioxide, water and heat as shown in the equation below:

Hydrocarbon + Oxygen à Carbon Dioxide + Water + Heat Released

Conventionally, NSE of marine fuels (which consist of predominantly hydrocarbons from petroleum sources) is calculated using a formula specified in Annex of ISO 8217 (Annex J of ISO 8217:2024) with acceptable accuracy. For marine fuels containing FAME, the NSE cannot be calculated using the formula specified in Annex J of ISO 8217:2024 and shall be measured using ASTM D240 method. FAME molecules contain the Carbonyl group and Ester bonds as shown in Figure 1 below and do not consist purely of carbon and hydrogen atoms.

Figure 1: An Ester of a Carboxylic Acid

The density of potential energy of a hydrocarbon is determined by the number of carbon to hydrogen bonds that can be replaced by oxygen to carbon (CO2) and oxygen to hydrogen bonds (H2O), in other words, the amount of energy released is dependent on the oxidation state of the carbons in the hydrocarbon. For marine fuel containing FAME, the FAME molecule itself contains oxygen atoms in the Carbonyl group and Ester bond. The Ester group of FAME has a carbon forming 3 bonds with oxygen atoms, this means esters are more oxidised than hydrocarbons and esters release less energy content when compared to hydrocarbon since higher oxidation reactions are needed for hydrocarbons.

The paragraphs above explain the reasons marine fuel containing FAME typically have lower energy content compared to conventional marine fuels, which consist of predominantly hydrocarbons and the calculated formula for NSE is not applicable to marine fuel containing FAME.

According to ASTM D240 test method, heat of combustion is determined by burning a weighed sample in an oxygen bomb calorimeter under controlled conditions. The heat of combustion is computed from temperature observations before, during, and after combustion, with proper allowance for thermochemical and heat transfer corrections. The average of gross specific energy (GSE) or gross heat of combustion, and NSE or net heat of combustion of MGO, VLSFO, HSFO and Bio-marine Fuels are tabulated in Table 1 below:

Note: The average GSE and NSE for each of the fuel types was obtained from at least 50 samples.

Based on Table 1, bio-marine fuel B30 has 8% lower energy content when compared to MGO. The energy content of bio-marine fuel will become lower when the FAME content is higher.

Energy content of marine fuel containing FAME shall be determined by ASTM D240 method and cannot be calculated using the current NSE formula, which is commonly used for the conventional marine fuels.

The discrepancy of NSE (or net heat of combustion) and GSE (or gross heat of combustion) of bio-residual marine fuels, B24 & B30, obtained from measurement using ASTM D240 and calculation using Annex J of ISO 8217:2024 is shown in Figure 2, 3, 4 & 5 respectively and tabulated in Table 2 and Table 3 respectively.

Graphical comparison of ASTM D240 vs ISO 8217 testing outcomes of Net and Gross Specific Energy (NSE/GSE) of B24 & B30 Bio-marine fuels

Table 2 and Figure 2 above show that the NSE obtained by calculations using Annex J of ISO 8217:2024 is approximately 3.5% higher for B24 when compared to NSE obtained by measuring using ASTM D240, this again proves that the calculated NSE of bio-marine fuel is not accurate, and that this formula is not applicable to bio-marine fuels. Clause 6.18 of ISO 8217:2024 stipulates that NSE (or net heat of combustion) of marine fuel containing FAME shall be measured using ASTM D240.

Situation to further understand higher fuel consumption rate of marine fuel containing FAME due to lower energy content

ScenarioA ship uses 5,612MT of VLSFO throughout the year during her Europe voyages (From the last port to Europe and up to the first port after Europe and within Europe).

Calculations if the use of Biofuel comes into play: If she decides to use Biofuel Grade of B24 for the same Europe voyages maintaining the same amount of power consumption from 5,612MT of VLSFO, she would need to lift 5,612 * 1.024 (10% of 24% BF) = 5,747 MT of Fuel as 24% Biofuel would contribute to 21.6% of equivalent energy compared to that of VLSFO if the Biofuel energy content is found to be 10% lower than that of VLSFO.

Conclusion & Maritec-NAIAS Recommendation

Based on the data evidence shared, it clearly indicates that bio-marine fuels have lower energy content when compared to conventional bunker fuels, which will contribute to a higher fuel consumption rate. Furthermore, the current formula used to calculate NSE of conventional marine fuels is not applicable to bio-marine fuel.

For efficient bio-marine fuel management onboard ships and for accurate measurement of energy content of bio-marine fuels, Maritec strongly recommends that Energy Content for all bio-marine fuel should be determined in advance and further, the NSE (or net heat of combustion) should be measured using ASTM D240 method before is it used onboard vessels.

Maritec-NAIAS provides latest ASTM D240 testing and other Enhanced Analysis options/packages for Alternative/Bio-marine fuels, in addition to standard regulatory testing requirements.

For more information on our Fuel Quality Testing services & solutions visit https://www.maritec.com.sg/services/Fuel_Testing&Solution or write to us at admin@maritec.com.sg

Click Here to Download the PDF copy of the Newsletter

Newsletter & Whitepapers

Fuel EU Maritime Regulation Effective 01 January 2025: How It Works, Compliance Requirements & More

Fuel EU Maritime Regulation Effective 01 January 2025:How It Works, Compliance Requirements & More

The FuelEU Maritime Regulation

With its impending implementation on 01 January 2025, the FuelEU Maritime Regulation will be enforced by the EU for all ships trading within the EU or European Economic Area (EEA). FuelEU Maritime sets ‘Green House Gas (GHG) Intensity’ targets (not to be exceeded) on the annual average GHG Intensity of energy used by vessels.

The GHG Intensity targets are strategically reduced every 5 years, set from 2025 up to 2050. This will start at a 2% reduction of GHG Intensity in 2025, increasing to 6% in 2030, and accelerating from 2035 to reach an 80% reduction by 2050.

Image 1: FuelEU Maritime targets as set from 2025 to 2050

How It Works & Key Aspects to Note

- GHG Intensity is measured as GHG emissions per energy unit (gCO2e/MJ) and, in turn, GHG emissions are calculated in a Well-To-Wake (WTW) perspective.

- The calculation takes into account emissions related to the extraction, cultivation, production and transportation of fuel, in addition to emissions from energy used on board the ship.

- The baseline for the calculation is the average WTW GHG Intensity of the fleet in 2020 (HFO 91.16 gCO2e/MJ).

Image 2: Well-To-Wake (WTW) Illustration

- The GHG intensity requirement applies to 100% of energy used on voyages and port calls within the EU or EEA, and 50% of energy used on voyages into or out of the EU or EEA.

- Not complying with the WTW GHG intensity target from 2025 will result in a penalty of approx. EUR 30 per tonne of VLSFO-equivalent.

- Owing to its GHG Intensity, fossil fuels except LNG will not comply from 2025 onwards.

- Vessels require only approx. 15% adoption of B24 BioFuel for EU voyages fuel consumption to avoid penalty

- Use of B24 BioFuel is a “ready solution” in your marine energy transition journey.

- Ship owners must purchase fuel from Traders with EU recognized Sustainability Certification (such as ISCC EU)

Recommended Plan of Action for Ship Owners

CTI-Maritec recommends the following as key overarching actions to help set you on course in your journey towards compliance with FuelEU Maritime, however must state that the same is not limited to only the below:

- Submit a FuelEU Monitoring Plan to an accredited verifier. This plan should outline how you intend to monitor and report emissions for each ship in your fleet. This should be completed by 31 August 2024 or within 2 months after first port of call in 2025.

- Start reporting key data related to FuelEU Maritime from 1 January 2025. This data includes fuel consumption, carbon emissions, and distance travelled.

- Submit the individual ship’s FuelEU reports by 31 January 2026.

- By 30 April 2026, have the compliance balance approved in the FuelEU Maritime database

- By 30 June 2026, have the FuelEU Document of Compliance on board. This is also the penalty payment deadline.

What Mechanisms to Adopt to Ensure You are Meeting your FuelEU Maritime Targets

- Use energy sources of a lower well-to-wake GHG intensity, such as sustainable biofuels like B24 BioFuel, renewable fuels of non-biological origin (RFNBO), recycled carbon fuels (RCF), Fossil LNG/LPG, shore power, wind-assisted propulsion, etc.

- Ensure fuel is purchased from traders with EU recognized Sustainability Certification (achieved when systems such as the ISCC EU scheme is adopted)

- Use of flexibility mechanisms, such as borrowing an advance compliance surplus from the next year (maximum 2%, not allowed for two consecutive periods) or include the ship’s compliance balance in a pool of ships (also possible in collaboration with other companies)

- For Fuel Suppliers: Integrate robust systems established by credible institutes such as the ISCC (International Sustainability and Carbon Certification) EU Schemes into your organisations procedures, which ensures sustainability in feedstock production (e.g. Proof-of-Sustainability documents from fuel traders), traceability of sustainable products through the supply chain as well as credible, verified reductions of life cycle emissions. With the ISCC system recognized under the EU’s revised Renewable Energy Directive (“RED II”) as well as other major energy markets, ISCC certification is set to play a major role under the upcoming FuelEU Maritime regulation and beyond.

CTI-Maritec offers FuelEU Maritime and ISCC services & solutions for both Vessels and Traders, such as:

- A One-stop certification solution for Traders to achieve ISCC EU.

- Holistic Training, Consultancy and Advisory services for ship managers and ship owners in support of achieving FuelEU Maritime targets.

For more information on our FuelEU Maritime and ISCC EU and ISCC Plus Certification services & solutions write to us at admin@maritec.com.sg

Sources:

- Regulation (EU) 2023/1805 of the European Parliament and of the Council of 13 September 2023 on the use of renewable and low-carbon fuels in maritime transport

- Renewable Energy Directive

- https://www.dnv.com/maritime/insights/topics/fueleu-maritime/

- https://www.iscc-system.org/markets/sustainable-transport-fuels/sustainable-marine-fuels/

Click Here to Download the PDF copy of the Newsletter

Newsletter & Whitepapers

CTI Group Acquires & Integrates NAIAS Labs

CTI Group Acquires & Integrates NAIAS Labs

Following the acquisition of Singapore based MARITEC PTE. LTD. 4 years prior, CTI Group has acquired Greek based NAIAS Labs to further strengthen the organisation’s MARINE ENERGY TRANSITION solutions.

.png)

Picture Caption: Senior Management from CTI-Maritec and NAIAS Labs address team members to mark the momentous occasion of the full acquisition and integration of NAIAS Labs into the CTI-Maritec family in Piraeus, Greece, on 29 November 2024.

As of 29 November 2024

PIRAEUS, GREECE: Centre Testing International Group Co., Ltd. (hereinafter referred to as CTI Group) has successfully completed the full acquisition of the Greek company NAIAS SCIENTIFIC ANALYTICAL LABORATORIES SOCIETE ANONYME (hereinafter referred to as NAIAS Labs) and commenced the seamless integration of NAIAS Labs into MARITEC PTE. LTD.’s (hereinafter referred to as CTI-Maritec) network.

On 29 November 2024, senior management of CTI-Maritec, the marine arm of CTI Group, and NAIAS Labs gathered together at NAIAS Labs, to officially welcome NAIAS Labs into the CTI-Maritec family. The integration comes to fruit as a result of the focused drive to expand the company’s global network in the MARINE ENERGY TRANSITION and ENVIRONMENTAL COMPLIANCE & RISK sectors and strategically bring even greater value to clients worldwide.

Richard Shentu, CEO of CTI Group, stated: “This M&A was driven by our shared commitment to excellence and innovation. It will strengthen our position as a global leader in marine environmental & fuel services and the upcoming SAF aviation fuels testing, and will further extend our capabilities in helping our clients navigate smoothly along the decarbonisation, environmental compliance and energy transition route. By synergizing the NAIAS’ local footprint in European markets and it’s potentiality with CTI’s robust global networks, we are poised to deliver even greater value to our clients worldwide.”

Dr. Marios Tsezos, on behalf of NAIAS Labs, stated: “Through synergy of the two entities’ robust capabilities and their global networks, both CTI-Maritec and NAIAS Labs customers will benefit largely from the greater accessibility to the wide-range of services & solutions offered, across the EU, Asia, Asia-Pacific and Americas regions, with faster turn-around-times, state-of-the-art know-how and technologies.”

Andreas Lougridis, the General Manager of Europe, the Middle East and Africa (the EMA Region) of CTI-Maritec, stated: “Together, joining hands with the team of NAIAS Labs, we are very excited to further elevate, for our clients, our services of Fuel Testing & Solutions (including Biofuel & Alternative Fuels), Lube Oil Analysis, Discharge Water Compliance Services, Inventory of Hazardous Material (IHM) & IHM Maintenance Services, Responsible Ship Recycling (RSR) Supervision, Asbestos Management Solutions, NDT & UTM Services, Bunker Quantity Survey, Cargo Inspection and ISCC Certification & Energy Consultancy, among others.”

- Media Contact Email: marketing@maritec.com.sg

- About CTI Group: https://www.cti-cert.com/en/about/Overview | Click Here to go to CTI LinkedIn Account

- About CTI-Maritec: https://www.maritec.com.sg/about | Click Here to go to CTI-Maritec LinkedIn Account

- About NAIAS: https://www.naiaslabs.com/about-us/ | Click Here to go to NAIAS Labs LinkedIn Account

News

China Port State Control (PSC) inspections detained 3 vessels found with BWMS deficiencies

China Port State Control (PSC) inspections detained 3 vessels found with BWMS deficiencies

Introduction

The Port State Control (PSC) is an inspection regime for countries to inspect foreign-registered ships in port other than those of the flag state and take action against ships that are not in compliance.

During September 2024 inspections, the China PSC detained 3 vessels, which were found to have deficiencies related to the vessel’s Ballast Water Management Systems (BWMS) and procedures in accordance with IMO’s Ballast Water Convention (Resolution MEPC.387[81]).

Deficiencies Recorded

The following are the BWMS deficiencies recorded:

Vessel A, detained at Rizhao port on 10 September 2024:

|

Area |

Deficiency |

Nature of Deficiency |

|

Pollution prevention – Ballast Water |

14811 – Ballast Water Management System |

Not Operating as required |

Vessel B, detained at Zhanjiang port on 9 September 2024:

|

Area |

Deficiency |

Nature of Deficiency |

| Certificate And Documentation – Ship Certificates | 01136 – International Ballast Water Management Certificate |

Expired |

Vessel C, detained at Dalian port on 6 September 2024:

|

Area |

Deficiency |

Nature of Deficiency |

| Certificate And Documentation – Ship Certificates | 01136 – International Ballast Water Management Certificate |

Expired |

|

Pollution prevention – Ballast Water |

14811 – Ballast Water Management System |

Not Operating as required |

The above vessel deficiencies reported by the PSC are yet another indication of the strengthened drive by authorities towards more stringent monitoring of Ballast Water Management System procedures in the universal pursuit towards greener shipping. For detailed information on the inspection records visit the Tokyo MoU website at https://apcis.tmou.org/public/.

For more information CTI-Maritec Ballast Water Management & other Discharge Water Compliance services please Click Here or please write to us at admin@maritec.com.sg .

CTI-Maritec Ballast Water Compliance Services & Solutions:

Unmatched Experience: Benefit from unmatched experience gained from providing worldclass services & solutions for onboard BWTS D2 commissioning testing, reporting and advisory solutions.

Innovative Solutions: Benefit from holistic solutions such as our ‘VGP Annual Compliance Program’ to manage your end-to-end needs as per the US EPA’s VGP requirements.

24×7 Attendance & Services: Benefit from speedy, efficient and highly professional services available 24×7, 365 days a year.