Maritec-Naias Joins Marine Fuels Alliance (MFA) to Strengthen Collaboration and Drive Industry Standards

Maritec-Naias Joins Marine Fuels Alliance (MFA) to Strengthen Collaboration and Drive Industry Standards

Maritec-Naias, is proud to announce its membership in the Marine Fuels Alliance (MFA), the independent global network dedicated to supporting, connecting, and promoting businesses across the bunker supply chain.

By joining MFA, our organisation gains access to a powerful platform that fosters collaboration, enhances visibility, and provides guidance in navigating the rapidly evolving marine fuels industry. Membership underscores the company’s commitment to transparency, sustainability, and innovation in the global shipping market.

Benefits of MFA Membership for Maritec-Naias & our Clients

- Industry Guidance: Access to expert insights and best-practice resources to meet regulatory and compliance challenges, which reflect significantly in our service enhancements for our customers.

- Global Visibility & Reach: The Alliance provides a platform to showcase expertise and services in global markets. This visibility helps members expand their reach and accessibility in international markets.

- Driving Standards: Participation in initiatives that improve transparency, reporting, and compliance across the bunker industry.

- Sustainability Focus: Contribution to the transition toward cleaner fuels and sustainable practices, aligning with global decarbonisation goals, which is a core value for Maritec-Naias.

“Joining the Marine Fuels Alliance,” said Toby Brooks, Commercial Director , “allows us to collaborate with industry peers, stay ahead of regulatory changes, and actively contribute to shaping the future of marine fuels. We are excited to be add support to MFA’s network and looking to deliver greater value to our customers and partners.”

About Marine Fuels Alliance

Founded in 2022, the Marine Fuels Alliance is an independent organisation that supports businesses across the marine fuels supply chain. MFA provides guidance, promotes transparency, and connects stakeholders to strengthen the industry’s resilience and sustainability. Membership is a strategic move, highlighting collaboration, visibility, and sustainability.

Maritec-Naias Exhibits at China MARINTEC 2025

Maritec-Naias Exhibits at China MARINTEC 2025

What an incredible Marintec China 2025!

From showcasing our latest solutions in the areas of Marine Bunker Fuel Oil testing, Lube Oil Testing, Ballast Water testing as per IMO & VGP Regulatory requirements and HKC regulatory requirements for HazMat management, among others, to meaningful conversations, our booth was a hub of innovation and collaboration with industry leaders, partners, and visitors from across the globe.

A heartfelt thank you to everyone who visited us and engaged with our team – jointly building up on partnerships that will shape the future of maritime compliance and testing.

Until next time, let’s keep pushing boundaries together!

Cooking Up a Greener Future!

Cooking Up a Greener Future!

Steered by the culinary pros at Boroume, a Greece based non-profit organisation committed to sustainable kitchen practices, our global team cooked up a storm during a mouth-wateringly insightful team building get-together.

Understanding and applying the fundamental values of true sustainability begins in the simplest of tasks, like our daily cooking habits. Be it wholesome soup from offcuts & vegetable stems or apple bread & croutons made from days old bread, the workshop concept worked towards teaching resource efficiency and waste minimisation.

Thank you Boroume for a wonderful evening whilst helping us build on our sustainability goals

Seminar Focused at PSC CIC 2025 held in Singapore in Collaboration with CCS

Seminar Focused at PSC CIC 2025 held in Singapore in collaboration with CCS

Best Practices for PSC CIC 2025 on Ballast Water Management: Expert insights, avid discissions & invaluable learning!

The seminar held in Singapore on 30 September 2025, in collaboration with our esteemed colleagues at China Classification Society (CCS), was an immense success. We extend a big thank you to CCS for partnering with us to deliver a 360° session grounded in expert know-how and unmatched technical proficiency.

Liu Junzhao, Fleet Manager / Senior Technical Support from CCS, along with Keith Soh, Operations Manager, and Ratna Fauzi, Manager – Client Services from Maritec-Naias, provided our participants with thorough insights into the complexities of the current Port State Control Concentrated Inspection Campaign (PSC CIC). They shared robust analysis of the deficiencies observed in the latest inspections and emphasised the importance of being fully prepared in the critical compliance areas of Ballast Water Management.

An element that notably captured the audience’s attention was Maritec-Naias’s CIC Readiness Checklist – a carefully designed ‘tool’ aimed at providing crew members with the thorough guidance they need in achieving compliance.

With over a decade of experience in leading BWM compliance services & solutions, our team at Maritec-Naias offers the support needed to ensure preparedness for 2025 PSC CIC.

Register for Maritec-Naias Ballast Water Management Readiness Checklist & Consultancy Services at maritec.com.sg/service/cic and our team will be intouch with you to share the checklist and assess your requirements.

Maritec-Naias Senior Management attends ARACON 2025

Maritec-Naias senior management attends ARACON 2025

ARACON 2025 – Where innovation met strategy head-on!

Our Commercial Director, Toby Brooks, and GM – EMA Region, Andreas Lougridis, attended 2 dynamic days of ARACON 2025 in Rotterdam where key members of the marine fuel and shipping industries came together to connect, learn, and shape the future of shipping.

From insightful panels on decarbonisation and digitalisation to powerful conversations on resilience in an unpredictable market, this year’s theme – “Keeping Agile: Future Proofing the Marine Fuel Supply Chain” – couldn’t have been more timely.

The team’s key takeaways, deeply pertinent to Maritec-Naias’s future-forward & intuitive services and solutions, were:

- The growing role of biofuels and alternative energy sources

- Navigating regulatory shifts with agility and foresight

- Strengthening collaboration across the supply chain

As an organisation, we are always grateful for the opportunity to connect with industry leaders, innovators, and changemakers. Here’s to building a more sustainable and adaptive maritime future!

Maritec-Naias attends Istanbul Maritime Forum 2025

Maritec-Naias attends istanbul Maritime Forum 2025

Invaluable connections with visionary leaders, innovators, and maritime professionals made the Istanbul Maritime Forum 2025, hosted by the IGGS Group, an unforgettable success!

Our team comprising of Toby Brooks, Global Sales Director, Andreas Lougridis, GM – EMA Region & Emre Karacaoğlu, Turkey Operations Manager, in attendance for this two-day (07-08 October 2025) invitation only event, were especially galvanised by the expert speakers & strategic sessions held.

From decarbonisation strategies to digital transformation, the conversations were bold, insightful, and future-focused – all in sync with Maritec Naias’s core areas of excellence and vision for our continued support of the Maritime industry’s energy transition and environmental compliance goals.

Until next time, Istanbul!

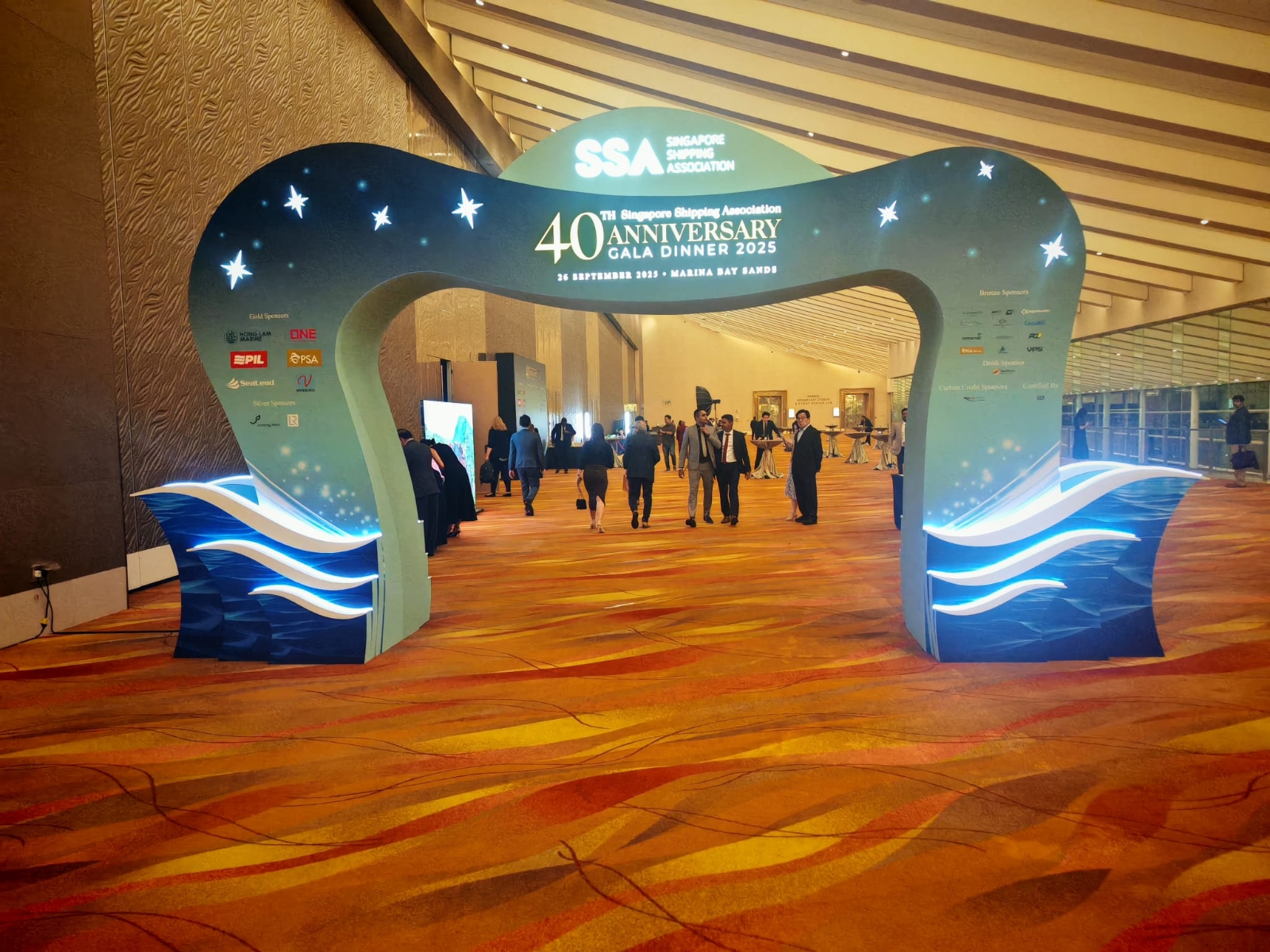

Singapore Shipping Association (SSA) 40th Anniversary Gala Dinner 2025

Singapore Shipping Association (SSA) 40th Anniversary Gala Dinner 2025

What an unforgettable evening at SSA’s 40th anniversary gala dinner!

The Singapore Shipping Association (SSA) 40th Anniversary Gala Dinner was truly remarkable! It was an honour to join esteemed colleagues and stakeholders in celebrating this milestone in Singapore.

The evening reminded our team of the importance of collaboration and innovation in shaping the future of the maritime industry. A big thank you to the organisers for hosting such a memorable event.

From inspiring speeches to meaningful networking, the event was a testament to the strength and unity of our maritime community.

Here’s to the next 40 years of success and growth!

Hong Kong Convention now effective on 26 June 2025: Are you aware of the requirements & applicability?

Hong Kong Convention now effective on 26 June 2025: Are you aware of the requirements & applicability?

INTRODUCTION

The Inventory of Hazardous Materials (IHM) requirements, which are a crucial component of the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships (HKC) regulation, signify a worldwide initiative to govern the sustainable practices involved in ship recycling processes.

Following almost 16 years of anticipation for its ratification, the HKC has officially come into effect on June 26, 2025, after Liberia and Bangladesh achieved Contracting State status in June 2023, thereby fulfilling the minimum ratification requirement. Currently, a total of 24 states have become Contracting States[2] to the HKC.

In accordance with the established regulations, all newly constructed and existing vessels are mandated to create IHM Part I by June 26, 2030, and must secure either the International Certificate (IC) or the Statement of Compliance (SoC), depending on which is applicable. Additionally, the Ship Recycling Facility is required to have the Document Authorization of Ship Recycling Facility (DASR), which will be issued by the Administration or a Recognized Organization.

The preliminary survey must be aligned with the renewal surveys mandated by other relevant statutory surveys, adhering to the principles set forth in the Survey Guidelines under the Harmonized System of Survey and Certification (HSSC), 2011.

Furthermore, an International Ready for Recycling Certificate (IRRC) will be granted to the vessel during its recycling phase, necessitating the preparation of IHM Parts I, II, and III, the Ship Recycling Plan, and the Certification/DASR of the Ship Recycling Facility during the final survey.

APPLICABILITY

HKC applies to:

- Ships[1] more than 500 gross tonnage

- Ships[1] flying with the flag of a Party

- Ships[1] flying with the flag of a non-Party operating under Party’s authority

- Ship Recycling Facilities operating under Party’s jurisdiction

IHM MAINTENANCE REQUIREMENTS

In accordance with the citation from MEPC.379(80) sections 4.3.1 and 4.3.3, it is essential that the IHM Part I is properly maintained and updated. This includes ensuring the continuity of the Inventory, particularly in relation to the name, flag, and shipowner, which should reflect the most current particulars of the ship[1].

Shipowners are required to develop an IHM Maintenance procedure and/or manual that is incorporated into the shipowner’s safety management system. Additionally, they must designate an individual responsible for IHM Maintenance, commonly referred to as the IHM Designated Person (IHM DP). The standard procedure for maintaining the Inventory involves gathering a Material Declaration (MD) and a Supplier Declaration of Conformity (SoC) for items suspected of containing hazardous materials supplied to the ship[1] for new installations and repair activities. An indicative list of suspected items is available in the MEPC.379(80) guidelines.

If a hazardous material is identified above the designated threshold values in a product, the IHM DP is required to update the Inventory and issue a new revision that includes the date and revision number. The IHM DP must also document the activities performed in a change log.

To effectively manage IHM Maintenance, which is centralized, fully digitalized, and meticulously maintained, ship owners or managers may engage the services of a reliable third-party service provider. This provider will manage all administrative aspects of IHM Maintenance at either a vessel or fleet level.

During the IHM renewal survey, in accordance with Regulation 10.1.2, the survey must confirm that Part I of the IHM meets the convention’s requirements. This necessitates that both the shipowner and the ship ensure the Inventory is properly maintained to prevent any deficiencies from being identified during the survey.

PORT STATE CONTROL (PSC) PROTOCOL

It is important to note that the Paris Memorandum of Understanding on Port State Control (Paris MoU) is incorporating the HKC as a pertinent instrument. This incorporation is set to be implemented from July 1, 2025, into its inspection framework, and shipowners must ensure that their vessels adhere to the stipulations of the convention.

For more information on Maritec-Naias IHM Compliance Services visit IHM & Recycling on our website.

Foot Notes:

[1] Ship can be categorized under “New Ship” and/or “Existing Ship” based on the following:

- 26 June 2025 (Contract date)

- 26 December 2025 (Keel laid, no contract in place)

- 26 December 2027 (Delivery date)

- Existing Ship: a ship which is not a new ship based on above parameters

[2] Contracting States: Bangladesh, Republic of the Congo, Ghana, India, Japan, Liberia, Marshall Islands, Pakistan, Panama, São Tomé and Príncipe, Serbia, Türkiye, Belgium, Croatia, Denmark, Estonia, France, Germany, Luxembourg, Malta, Kingdom of the Netherlands, Norway, Portugal, Spain.

Click Here to Download the PDF version of the Newsletter

Newsletter & Whitepapers

Maritec-Naias participates at Nor-Shipping 2025

Maritec-Naias participates at Nor-Shipping 2025

On 4th June 2025, after a full day at the exhibition, over 100 guests came together to unwind, catch up, and raise a glass in good company – all in a relaxed, welcoming space at Café de la Mar, just a short stroll from Oslo Central Station.

Maritec-Naias was delighted to be one of the sponsors and co-hosts of the evening, bringing together like-minded industry players to collaborate with, learn from, and build more up on. It was a strengthening moment to reinforce what we already have – and plant a few new seeds for our journey ahead in the EU.

From strategic conversations to spontaneous encounters, the entire Nor-Shipping 2025 week was all about building relationships and understanding where the industry is heading.

Refreshing new solution for marine energy -testing and compliance in Europe

Refreshing new solution for marine energy -testing and compliance in Europe

MARITEC-NAIAS represents a refreshing new solution for marine energy testing and compliance in Europe. Originally founded in 1999 in Singapore, MARITEC has built a strong global legacy in marine fuel oil testing. In 2020, the company was acquired by CTI Group, one of the world’s leading publicly listed TIC conglomerates, to enhance its global marine services.

Expanding into Europe through Strategic Acquisition

Today, MARITEC continues to make strides in the market, particularly following the successful acquisition and integration of NAIAS Labs in November 2024, which is among Greece’s largest laboratories for fuel and Lubricant Oil (LO) testing. The merger, now operating as MARITEC NAIAS, is strategically positioned to provide strengthened value to its clients through laboratories located in Singapore, China, and Greece. This, combined with extensive experience in catering to the Asian, Greek, and EU shipping markets, delivers leading services to its clientele, backed by its unique industry expertise.

A Vision Rooted in Compliance and Innovation

This recent acquisition underscores the vision and dedication of the core team and leaders of Maritec Naias, A member of the CTI Group to become the most dependable technology-driven green services partner for the shipping industry. At the outset of our journey more than 15 years ago, Global President, John Ren Di instinctively established and launched the first service line for Hazardous Materials (HM) compliance through inspection, testing and reporting shortly after the adoption of the 2009 Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships (HKC).

Evolving with International Regulations

As the International Maritime Organization (IMO) and the European Union (EU) made significant advancements in establishing rigorous targets for the management and disposal of Hazardous Materials (HM) within the shipping sector, John identified considerable challenges and gaps in meeting these objectives for operational vessels. To adhere to the regulatory standards, vessels in operation were required to create an Inventory of Hazardous Materials (IHM), obtain certification, maintain accurate records, and consistently update the IHM.

Additionally, vessels undergoing recycling had to fulfil all IHM requirements and comply with existing recycling regulations. This critical demand marked the inception of our market presence, which has since evolved into a leading global position in offering IHM services and solutions on over 5000 vessels.

Fueling the Future: Decarbonisation and Expansion

In 2023 the EU launched the EU Emissions Trading System (EU ETS), a cap-and-trade initiative designed to mitigate greenhouse gas emissions, which was further reinforced by the FuelEU Maritime Directive in 2025, establishing the first obligatory framework for decarbonizing shipping.

Observing the growing regulatory requirements and with an eye on the future, Maritec continued to invest towards the upgrade and enhancements our laboratory capabilities – markedly with the acquisition of NAIAS Labs to offer stronger global reach and testing services for alternative fuel, lubricants, and discharge water for clients worldwide.

Strengthening the Global Sales Force

Motivated by this vision, Toby Brooks, former BV Class, Senior Management at BV Solutions and Deputy Director of the Isle of Man Ship Registry, became the Global Sales Director at Maritec-Naias in early 2025. Located at Maritec-Naias’s newly established office in the UK, Toby is strategically positioned to bring the company’s advanced services and solutions to European markets.

Toby recognises the demanding challenge and complexity of compliance with decarbonisation directives and joins an experienced team in tailoring comprehensive solutions that lend a helping hand to international marine operations. He believes in listening to the needs of industry partners and in shaping and supporting a compliance process that drives sustainable long-term change. With a commitment to decarbonisation goals and an ever-growing footprint of technical expertise and testing facilities, Toby is confident Maritec-Naias is best positioned to deliver services that verify and substantiate investments made in energy efficiency and green technologies.

Driving Carbon Reduction Across Europe

Konstantina Aravantinou, a Naval Architect and Marine Engineer, with previous roles as Senior Engineer at DNVGL and Sales Manager at WÄRTSILÄ GREECE S.A., also joins Maritec-Naias as West Europe’s Sales Manager in May 2025. Konstantina is equally aligned to the vision of Maritec-Naias, drawing on her extensive experience in design and engineering. She is dedicated to supporting clients with carbon reduction and energy efficiency objectives.